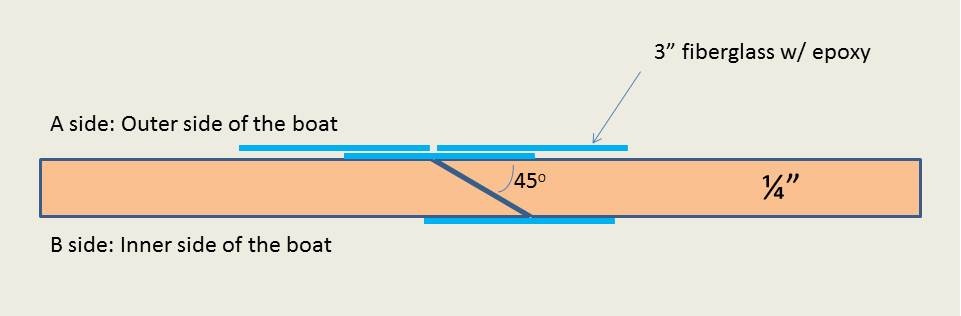

Types of joints used for wooden boat building. there are three usual ways of joining plywood panels together: butt joints, scarf joints and puzzle joints. the pre-cut joints in our kits are either of the scarf or puzzle type. butt joint. for a butt joint, the edges of the wood are pressed together and a backing block affixed over the joint.. The most bulletproof method is do all three: bed the joint, through-bolt it, then glass it over. unfortunately, many hull-deck joints are of rather poor quality. the most common practice, especially on mass-produced boats, is to bed the joint with an adhesive sealant and fasten it with self-tapping screws rather than bolts.. Home boat design forums > construction > boatbuilding > wooden boat building and restoration > scarf joint discussion in ' wooden boat building and restoration ' started by sleepyweasel , sep 17, 2012 ..

Pre-cut & cnc plywood wooden boats kits, wooden boat kits offer fully customisable cnc cut flat pack wooden boat kits at reasonable prices.. myboatplans® 518 boat plans - high quality boat building, instant access to 518 different plans - from small wooden boat plans to large sailboat plans - free boat plans.. Hi all, excited to be here and find the site very interesting. i'm trying to build a small duck boat out of plywood, via stitch and glue. just tried my first scarf joint and used a power planer to do it.. Boat building wood joints an additional benefit of aluminum is the fact that is comparatively gentle and malleable, regardless of its durability. this means it is easy to shape into whatever type needed, such as the curved shapes needed for boats..